Hot rolled seamless steel tube in the process of urban construction and mechanical products manufacturing plays a vital role. Its production and processing technology under the trend of expanding market demand also got very fast development. Hot rolled seamless steel tube production process mainly includes the circular tube embryo, heating, perforation, pipe mill, set (reduction) diameter, cooling, leveling; By over-packaging perforation, pipe mill, sizing as the main deformation process. Sizing mill, rolling out is the perforation of capillary, further sizing rolling, improve the quality of steel pipe outer surface. After sizing steel pipe, small diameter deviation, smaller ovality, straight degree good, smooth surface.

EACON frequency converter has a lot of mature application in the industry, has obtained the obvious technical and economic effect, and effectively raise the customer production.

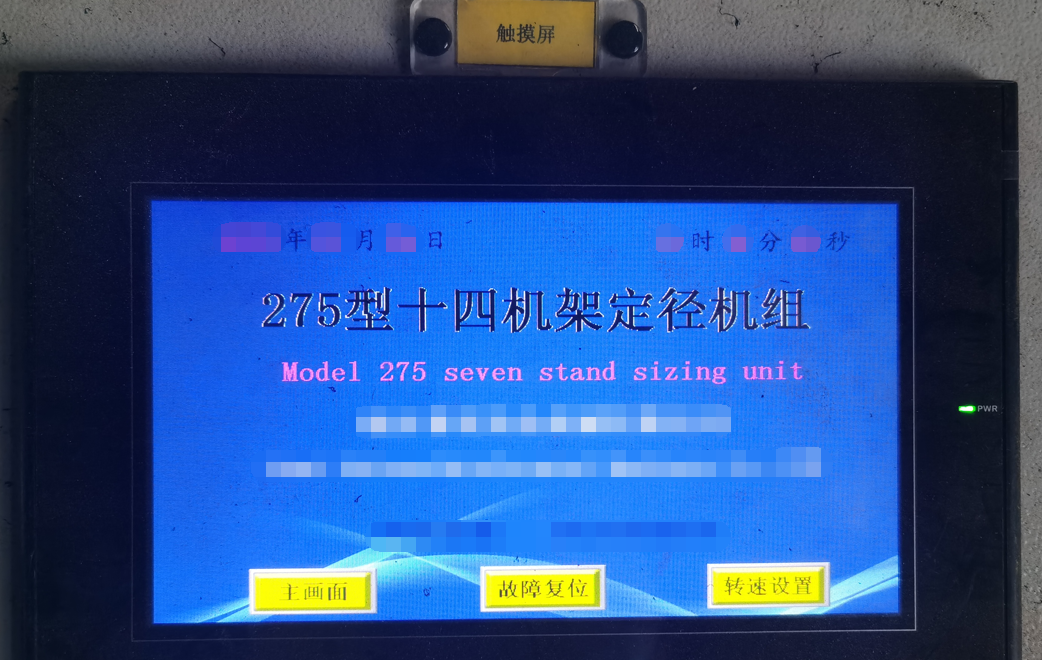

The system configuration

14 EC6000 series frequency converter used in this system to control the 14 sets of sizing rack drive alone, with a motor drive for each frame, each frame has noninterference of speed control and drive system. System use PLC + touch screen, through 485 for each inverter frequency adjustment and running condition of the real-time monitoring. This way of single drive speed, flexible application is wider in scope for inverter communication response and speed response to demand higher.

Application advantages

Effectively reduce the system’s design and maintenance cost, convenient operation, saving energy consumption, than the collective over 20% of energy transmission, extend the service life of the machinery;

Communication response is fast, simple wiring, high-speed communications don’t throw the frame, make the machine more stable operation;

With the industry’s leading motor vector control algorithm, make the motor temperature rise significantly lower sizing mill equipment, starting torque of up to 180%, the motor power is stronger;

High control precision, torque accuracy of plus or minus 5%, speed accuracy + / – 0.03% or less, to improve the production process, improve the control precision of the equipment, pipe rolling effect is good, high efficiency;

Protect the powerful, can provide perfect over-current, over-voltage, undervoltage, overload protection function, such as overload capacity 150% rated current 1 minute, make the system run more stable and reliable.

Post time: Apr-24-2023