With the continuous development of China’s industrialization, wire drawing machines have played an indispensable role in wire processing, especially in steel wire, copper wire, plastic, bamboo chopsticks, wood, wire and cable industries. Wire drawing machines can be divided into metal wire drawing machines, plastic wire drawing machines, bamboo and wood wire drawing machines according to their uses. Among them, the in-line wire drawing machine is the main production equipment for metal processing. It can cold draw the steel wire to the required specification at one time. With high working efficiency and small equipment area, it is a common and more advanced type. However, it has higher requirements on the synchronization and dynamic response of the motor, and is the most difficult to control one of the wire drawing machines. Next, we will introduce the application of EN700 series intelligent inverter in in-line wire drawing machine.

Process introduction

The in-line wire drawing machine is a common metal wire processing equipment, which is mainly used for wire drawing processing of steel wire, copper wire, alloy wire, welding wire and other materials, and is composed of paying off, wire drawing and wire take-up. Details are as follows:

Paying off part: mainly feed the processed materials into the wire drawing part. At this stage, the cable can withstand large tension. Passive paying off is adopted. The motor is required to have large torque and stable running speed when starting and running at low speed.

Wire drawing part: the wire rods are drawn step by step through the drawing dies at all levels here (13 dies in total), and each level is driven by a frequency converter and a variable frequency motor. In this process link, it is required that the performance of the frequency converter is reliable, so that the motor has high electrical speed accuracy, fast dynamic response, constant wire tension, and continuous spinning, thus ensuring the quality of the finished product.

Winding part: It is mainly used to wind up the processed wire on the reel. It is required that whether it is starting to accelerate, stopping to decelerate, or running at a constant speed, it should be synchronized with the motor line speed of the wire drawing part to ensure a stable winding effect.

System configuration

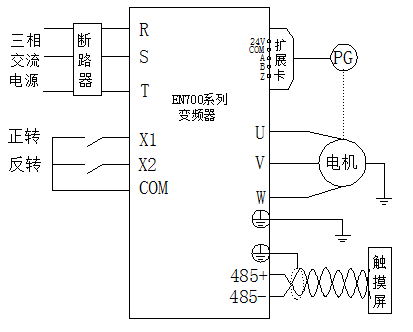

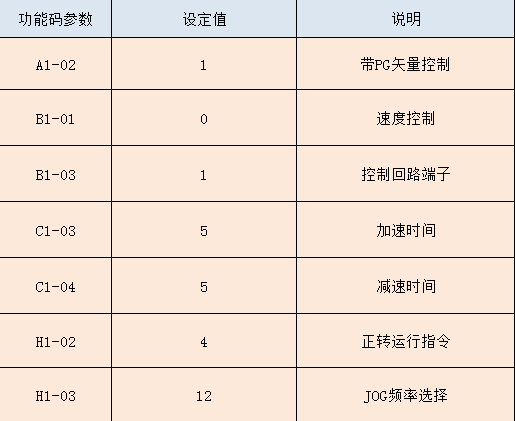

The field equipment system uses MODBUS communication for operation. Each set of equipment is equipped with 19 EENEN EN700 series intelligent frequency converters. For the wire drawing part, each level is driven by a frequency converter and a variable frequency motor. Each frequency converter is equipped with an expansion card to connect with the motor encoder to form a closed-loop vector control.

Post time: Jan-05-2023