Process requirements for large circular knitting machine

(1) It is required that the frequency converter has strong environmental resistance. Due to the high temperature of the on-site working environment and the cotton wadding, the cooling fan is easy to be blocked, damaged and the cooling hole is blocked.

(2) Flexible inching operation function is required, inching buttons are installed at many places of the equipment, and the frequency converter is required to respond quickly.

(3) In terms of speed control, three speeds are required. One is jogging speed, usually about 6Hz; The second is the normal weaving speed, the highest frequency can reach 70Hz; Third, low speed cloth collecting operation requires a frequency of about 20Hz.

(4) During the operation of the big round machine, it is absolutely forbidden to reverse and rotate the motor, otherwise the needle of the needle bed will be bent or broken. If it is a big round machine with single-phase bearings, it may not be considered. If the forward and reverse rotation of the system completely depends on the forward and reverse rotation of the motor, on the one hand, it is necessary to prohibit reverse rotation, and on the other hand, it is necessary to set DC braking to eliminate rotation.

Technical requirement

The Knitting Machine industry has relatively simple requirements for the control function of the frequency converter. Generally, the starting and stopping are controlled by the terminal, and the given frequency of the analog quantity or the given frequency of the multistage speed is used. The inching or low-speed operation is required to be fast, so the frequency converter is required to be able to control the low frequency torque of the motor. In general, the V/F mode of frequency converter can meet the requirements for large round machine applications.

Our solution is:

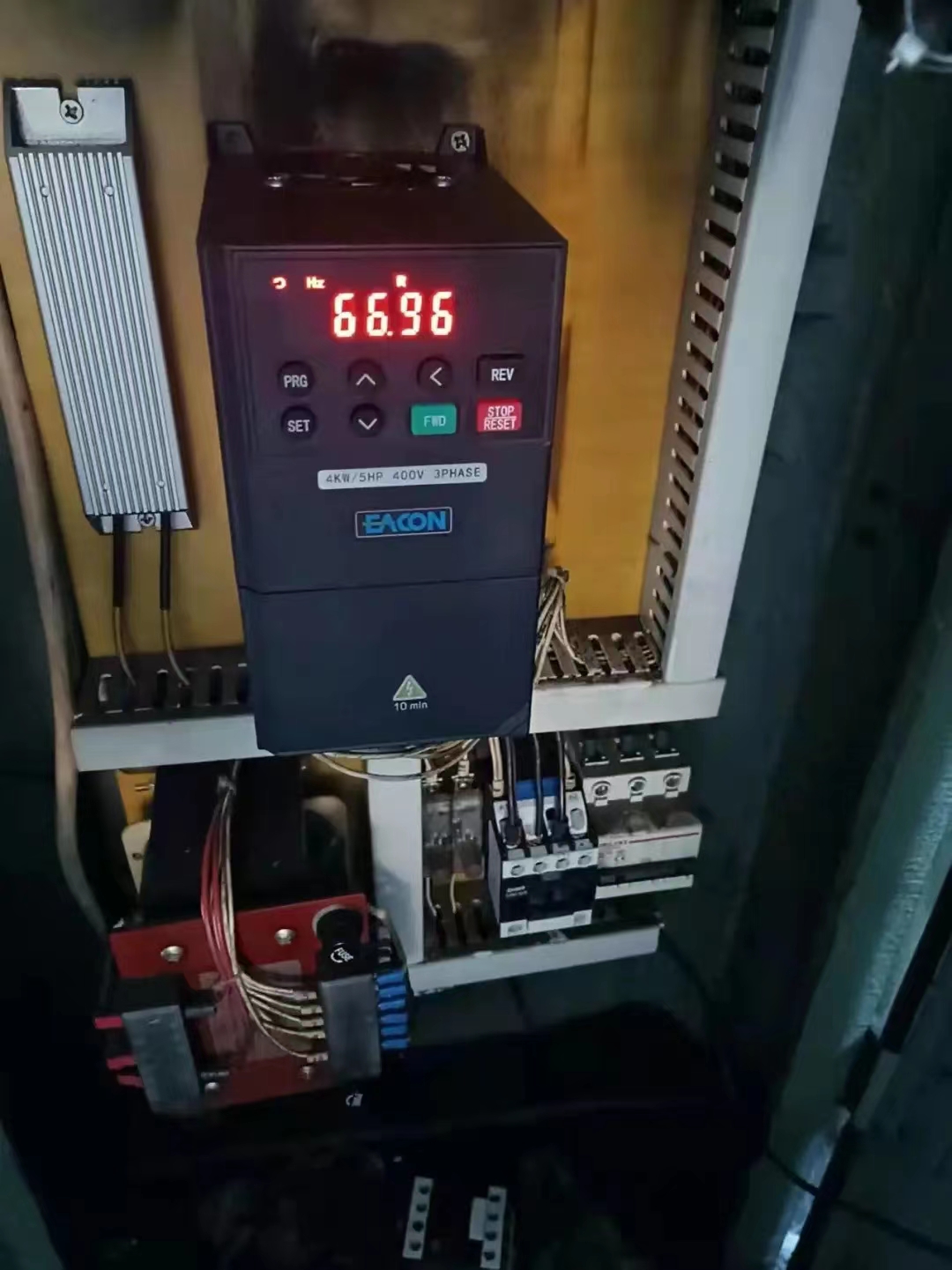

EC590 frequency converter, the power is 4kW

Product advantages:

1. S-type acceleration and deceleration for smooth start and stop.

2. Magnetic flux vector control mode, low frequency, large torque, fast response.

3. Deceleration plus DC braking function, stable shutdown and braking.

4. The reverse rotation prevention function is adopted to avoid needle breakage caused by reverse rotation of equipment.

5. Good heat dissipation design can fully meet the long-term operation of the equipment in a high-temperature environment.

Post time: Nov-21-2022